Results of scientific activity:

- Separator of plasma for industrial purposes unique by its capacity, operation stability and reliability is developed, produced and approved; this separator exceeds the best world analogues in 1,5-2 times by its capacity. The source of plasma is patented in Ukraine and in Russia, is now patenting in USA, Germany, Great Britain, France, Italy, Switzerland, Japan, South Korea and China. Firstly in the history of KIPT license for named source of plasma was passed to the Dutch company “Khauzer” and now the pilot specimen of the source is successfully tested in Holland.

- A series of nanostructure and nano compositional metallic and compositional mono- and polycomponent coatings with unique operational characteristics is produced for wide range of application in NP and other branches of industry.

- The extreme dependence of nano hardness of TiSiN coating on content of silicon is revealed. Maximum hardness (~33 GPa) was observed with silicon concentration of 7 weight % .

- To prevent large-scale accidents during the loss of coolant with the onset of steam-zirconium reaction with the dissociation of water, absorption of oxygen and release of hydrogen(LOCA, Fukusima-1) of nuclear reactor WWER processes of coating deposition for zirconium alloys are developed; such coatings will reli8ably isolate of Zr from interaction with water vapor at T=1100oC during 3600. Besides, coatings guarantee the increase of mechanical, corrosion and erosion characteristic of fuel tubes.

- Testing of nitride multy component coatings on systems Ti-Al-Y-Re-V, Ti-Al-Ni-Cr-N, Ti-Si-Y-N, Ti-Mo-Fe-Y-N for wear resistance was performed. It was revealed that addition to nitrides on the base of titanium of impurities Ni, Cr, Si, Fe doesn’t promote the increase of wear resistance of coatings. Alloying of nitride coatings Ti-Al-N by low impurities of Y and Re appears to be more effective. Record indexes were observed for coating produced from cathode of composition Ti0,49 Al0.50Y0,.006 Re0,0005 which have withstood 14 hours of cavitation tests with the loss only 30 mkg of the mass;

- Study of the effect of parameters of diamond films deposition on the synthesis of textured diamond films is performed. On the base of X-ray diffraction study and investigation of the structure of diamond coating surface the range of parameters of diamond coatings with different texture in coordinates “temperature of synthesis of diamond coating-concentration of methane in gaseous mixture” is determined.

Books and publication:

"Vacuum arc"

аuthors:

I.I. Aksenov, A.A. Andreev, V.A. Belous, V.E. Strelnitskiy, V.M. Khorochikh

Main results of many years investigation and developments of Kharkov physical-technical institute in the field of vacuum-arc ion-plasma processes of coatings deposition and surface modification of materials are presented in this book. Methods of formation of the fluxes of metallic plasma generated by cathode spots of arc discharge in vacuum and gaseous medium of low pressure are described. Processes in interelectrode plasma, methods of ignition and stabilization of discharge in technological plasma sources are considered. Mechanisms being in the basis of processes of formation of functional coatings of metals, their composites of nitrides, oxides, carbides and their combinations are proposed. Data are presented on investigation of synthesis of micro- and nano structurized composition and multilayer coatings Extensive experimental and theoretical material on physics and technique of vacuum-arc synthesis of thin and super thon films of diamond-like carbon is presented, examples of commercial use of vacuum-arc methods diamond-like coatings deposition are presented, possibilities of their practical use are considered. Vacuum-arc processes of surface protection of uranium and other materials of nuclear power are described.

"Appliances vacuum-arc deposition of coatings"

authors: I.I. Aksenov, D.I. Aksenov, V.A. Belous

The book presents the fundamentals of physics and technology of vacuum arc plasma sources for the deposition of functional coatings. The methods of ignition and stabilization process in the discharge plasma sources. We describe the most common filter systems for cleaning plasma from particulate material eroding the cathode.

"Chronicles of Bulat"

authors: I.I. Aksenov, V.A. Belous

Book presents information on foundation, development and present state of KIPT NANU activity on ion-plasma methods, technologies and equipment for deposition of coatings in mechanical engineering, aviation, space, nuclear and traditional power (method of condensation with ion bombardment, facility «Bulat».

"Handling of spent nuclear fuel and radioactive waste"

authors: V.M. Azhazha, V.A. Belous, S.V.Gabelkov, E.A. Dzhur, I.M. Neklyudov

Book is devoted to the analysis of the state, problems and prospects of nuclear power development in technically progressive countries. Questions of raw materials mining, fabrication of fuel and fuel elements, types of reactors for electrical power production are considered in details. The special attention is paid to the problems of accumulation of spent nuclear fuel and waste, to safe methods and modern technologies of waste handling, storage and burial.

"Films of diamond like carbon"

authors: V.E. Strelnitskiy, I.I. Aksenov

The modern state of experimental investigation of amorphous diamond – like carbon films by vacuum-arc method is highlighted. Processes of deposition of films of hydrogenated diamond-like carbon by decomposition of carbon-containing gaseous compositions in glow discharge are examined.

"Vacuum-arc coatings"

authors: A.A. Andreev, L.P. Sablev, S.N. Grigoriev.

Physical processes occurring on electrodes and in interelectrode space of vacuum-arc discharge are examined. The main approaches to designing of vacuum-arc evaporators and their diagrams are described. Characteristics of wear-resistant vacuum-arc coatings including superhard nanostrucural coatings with the results of their use on instruments are presented.

"Vacuum arc in erosion sources of plasma"

аuthor: I.I. Aksenov

Results of investigation of author and collaborators in the field of formation of metallic plasma flows which is generated by cathode spots of arc discharge in vacuum and in gaseous medium of low pressure are ordered in monograph. Processes of ignition and stabilizing of discharge in technological plasma sources are examined.

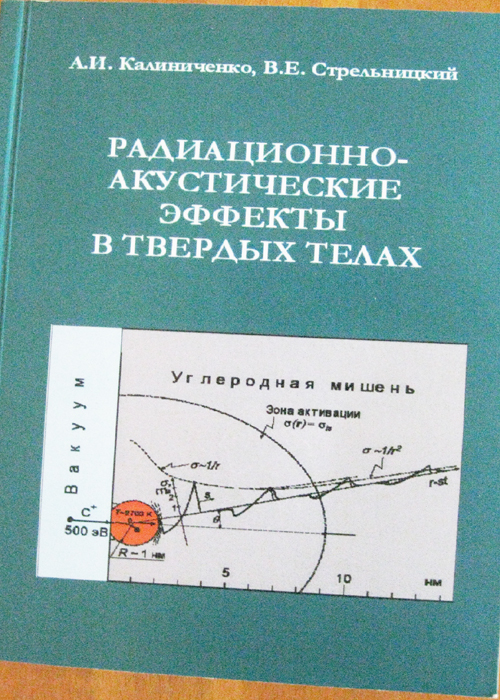

"Radiation-acoustic effects in solids"

authors: A.N. Kalinichenko, V.E. Strelnitskiy

In this book are presented results of theoretical and experimental investigations in the field of radiation acoustic of solid – new field of physics which studies sound phenomena arising during interaction of particles and radiation beam with solids of different nature. Influence of radiation-acoustic effects on processes of transfer, structure formation and break-down in irradiated solid is investigated. A number of practical application of radiation acoustic in technique of physical experiment, processes of radiation treatment of metals and in medicine is highlighted.

2015 year

Patent:

USA Patent # US 9,035,552 B2, Method and Device for Transporting Vacuum Arc Plasma / Vasyliev V. V., Strelnytskiy V. E.; assignee: NSC «Kharkov Institute of Physics and Technology» – No. PCT/UA2011/000105; Date: 04.08. 2013; Date of Patent: 05.19.2015.

Monographs:

И.И.Аксенов, Д.С.Аксенов, А.А.Андреев, В.А.Белоус, О.В.Соболь «ВАКУУМНО-ДУГОВЫЕ ПОКРЫТИЯ: технологии, материалы, структура, свойства.» Харьков, 2015, ВАНТ ННЦ ХФТИ, 380с.

Papers in foreign publishers:

- A.I. Kalinichenko, S.S. Perepelkin, V.E. Strel’nitskij. Intrinsic stresses in DLC coatings deposited in modes of DC and pulse bias potentials // Problems of Atomic Science and Technology., series Plasma Physics (21). -2015. Iss. 1(95) ‑ P.252-255.

- V.D. Ovcharenko, A.S. Kuprin, G.N. Tolmachova, I.V. Kolodiy, A. Gilewicz, O. Lupicka, J. Rochowicz, B. Warcholinski. Deposition of chromium nitride coatings using vacuum arc plasma in increased negative substrate bias voltage // Vacuum 117 (2015) 27-34.

- A.S. Kuprin, V.А. Belous, V.N. Voyevodin, V.V. Bryk, R.L. Vasilenko, V.D. Ovcharenko, E.N. Reshetnyak, G.N. Tolmachova, P.N. V'yugov. Vacuum-arc chromium-based coatings for protection of zirconium alloys from the high-temperature oxidation in air // Journal of Nuclear Materials 465 (2015) 400-406.

Papers in domestic publishers:

- 1. I.E. Kopanetz, G.D. Tolstolutskaya, A.V. Nikitin, V.A. Bilous, A.S. Kuprin, V.D. Ovcharenko, R.L. Vasilenko. The effect of Cr, Cr-N and Cr-Ox coatings on deuterium retention and penetration in zirconium alloy Zr-1Nb // PASТ. 2015. №5(99), p. 81 – 86.

2014 year

Monographs:

И.И.Аксенов, Д.С.Аксенов, В.А.Белоус. Техника осаждения вакуумно - дуговых покрытий. Харьков: ННЦ ХФТИ 2014. -280 с.

Papers in foreign publishers:

- Bilous, V., Borysenko, V., Voyevodin, V., Didenko, S., Ilchenko, M., Rybka, O., Kuznetsov, O. and Plisak, Y. //Layered Metal Composites: Newest Generation of Radiation-Protective Materials. Journal of Materials Science and Chemical Engineering, 2014, 2, 6-11, DOI: 10.4236/msce.2014.28002.

- Bilous, V., Borysenko, V., Voyevodin, V., Didenko, S., Ilchenko, M., Rybka, O. Radiation-Absorption Properties of AL–PB Multilayer Composites. Materials Science: Volume 50, Issue 1 (2014), Page 98-101(DOI) 10.1007/s11003-014-9696-5.

Papers in domestic publishers:

- В.А. Білоус В.М. Воєводін В.Є.Стрельницький С.Ю. Діденко О.В. Рибка М.І. Ільченко// Організація експериментально-технологічного комплексу для серійного виготовлення та тестування виробів і напівфабрикатів із алмазоподібних та металевих шаруватих композитів для провідних галузей машинобудування. Наука та інновації. 2014. Т. 10.№ 4. С. 5-21.

- I.I. Aksenov, V.A. Belous. Protecting coatings on uranium // East European Journal of Physics, 2014. – No. 4.

2013 year

Monographs:

- A.I.Kalinichenko, V.E.Strelnitskiy. Radiation-acoustic effects in solids.Kharkov: publisher of NSC KIPT NANU. – 2013. -320 p.

- I.I.Aksenov, V.A.Belous. Chronicles of “Bylat”.

- I.I.Aksenov, D.S.Aksenov, V.A.Belous “Technique of vacuum-arc coatings “. Kharkov, publisher FORT, 2013, 350 p.

Papers in foreign publishers:

- V. Belous, V. Vasyliev, A. Luchaninov, V. Marinin, E. Reshetnyak, V.E. Strel’nitskij , S. Goltvyanytsya,V. Goltvyanytsya. Cavitation and abrasion resistance of Ti-Al-Y-N coatings prepared by the PIII&D technique from filtered vacuum-arc plasma // Surface and Coatings Technology V. 223 (2013), pp. 68-74.;

- V.A.Belous, Yu.A.Zadneprovskiy, N.S.Lomino, O.V.Sobol. “Role of argon of its mixture with nitrogen in deposition of nitride condensates in the Ti-Si-N systems and in vacuum-arc processes”, Journal of Technical physics, Sanct-Petersbourg, Russia, 2013, Vol.83, Issue 7, p.69-76

- V. A. Belous, Yu. A. Zadneprovskiy, N. S. Lomino, and O. V. Sobol, Role of Argon in Its Mixture with Nitrogen in Deposition of Nitride Condensates in the Ti–Si–N System and in Vacuum Arc Deposition Processes, Technical Physics, 2013, Vol. 58, No. 7, pp. 999–1006.

- Belous V.A., Borodin О.V., Bryk V.V., Vasilenko R.L., Voyevodin V.N., Kuprin A.S., Ovcharenko V.D., Reshetnyak E.N., Tolmachova G.N. Radiation resistance of Ti-20Zr alloy in microcrystalline and nanocrystalline state // Functional materials. 2013, 20, №3, p. 351-356.

Papers in domestic publishers:

- Belous V.A., Kuprin A.S., Dub S.N., Ovcharenko V.D., Tolmacheva G.N., Reshetn`yak E.N., Litvin P.M. Structure and mechanical properties of protective coatings Ti-Al-Si-N deposited from separated plasma of vacuum arc// Superhard materials, 2013, No 1, p. 27-39

- Belous V.A., V`ygov P.N., Kuprin A.S., Leonov S.A., Nosov G.I., Ovcharenko V.D., Ozhigov L.S., Rudenko A.G., Savchenko V.I., Tolmacheva G.N. G.N.Khoroshikh V.M. Mechanical characteristics of fuel tubes made of alloy Zr1Nb after deposition of ion-plasma coatings// VANT, series “Physics of radiation damage and radiation material science”, 2013, No2 (84), p. 140-143

- Belous V.A., V`ygov P.N., Kuprin A.S., Leonov S.A., Nosov G.I., Ovcharenko V.D., Ozhigov L.S., Rudenko A.G., Savchenko V.I., Tolmacheva G.N., G.N.Khoroshikh V.M. Investigation of the effect of ion-plasma treatment on mechanical characteristics of zirconium alloys Zr1Nb. Physical engineering of the surface, 2013, v.11, No1, p.97-102

- Belous V.A., Nosov G.I. Modifying of the surface of reactor materials by ion-plasma irradiation. Preprint of KIPT 2013-6, Kharkov: NSC KIPT, 2013

- Leonov S.A., Khoroshikh V.M. Deposition of ion-plasma coatings from ranfombeams of plasma of vacuum arc. Preprint of KIPT 20123-4, Kharkov: NSC KIPT, 2013.

- KalinichenkoA.I., Perepelkin S.S., Strelnitskiy V.E. On forming of craters under ion bombardment.// VANT, series: “Physics of radiation damage and phenomena in solids”. -2013, No2/84.- P, 128-133.

- Kalinichenko A.I., Perepelkin S.S., Strelnitskiy V.E. On possibility of drop spraying of heavy metals by heavy ions of low and intermediate energies// Bulletin of Kharkov national university named by V.N.Karazin, No784. Series Physics “Nuclei, particles, fields”. 2013, issue 3/59/. – P. 57-64

- VolkovYu.Ya., Strelnitskiy V.E., Ushakov V.A. Synthesis of diamond in SHF plasma: equipment, films, application// Physical engineering of surface, 2013, v.11, No1, p.4-23

- Kalinichenko A.I., S.S.Perepelkin, V.E.Strelnitskiy. On formation of crater under ion bombardment //VANT, series ”Physics of radiation damage and radiation material science”, No2(84), p.128-133

- Kalinichenko A.I., V.E.Strelnitskiy. Radiation-acoustic effects in solids. Kharkov: publishing house of NSC KIPT NANU, 2013, 320 p.

- V.V.Vasiliev,V.E.Strelnitskiy. Vacuum-arc evaporator for generation of cathode plasma. Patent of Ukraine No101678. Priority from 08.04.2011, priority of 08.04.2011, registered 25.04.13, C23C 14/00

- V.V. Vasiliev, V.E.Strelnitskiy. Anode unit of vacuum-arc source of cathode plasma. Petent of Ukraine No101443, priority of 29.11.2011,registered 25.03.13, C23C 14/00C23 C-14/35

- V.A.Belous, A.S.Kuprin, S.N.Dub, V.D.Ovcharenko, G.N.Tolmacheva, E.I.Reshetnyak, I.I.Timofeeva, P.M.Litvin. Structure and mechanical properties of protective coatings Ti-Al-Si-N deposited from separated plasma of vacuum arc// Super hard materials, 2013, No1, p.27-39

Patents for our inventions:

- V.V.Vasiliev, V.E.Strelnitskiy. Vacuum-arc evaporator for generation of cathode plasma. Patent of Ukraine No101678. Priority from 08.04.2011, priority of 08.04.2011, registered 25.04.13, C23C 14/00

- V.V. Vasiliev, V.E.Strelnitskiy. Anode unit of vacuum-arc source of cathode plasma. Patent of Ukraine No 101443, priority of 29.11.2011, registered 25.03.13, C23C 14/00C23 C-14/35

- Anode unit of vacuum-arc source of cathode plasma. Patent application in Russia – 03.07.2013, No2013130658/07. 25.09.2013

- Decision about RF patent application: Method of transportation of vacuum-arc plasma with filtration from macro particles and device for its realization”.

- D.S.Aksenov, I.I.Aksenov. Facility for transportation of fluxes of vacuum-arc plasma//Patent of Ukraine No103692, 11.11.2013.

2012 year

- I.I.Aksenov, A.A.Andreev, V.A.Belous, V.E.Strelnitskiy, V.M.Khorochikh. “Vacuum arc. Sources of plasma, deposition of coatings, surface modification”, Monograph. Naukova dumka, 2012.

- V.A.Belous, Yu.A.Zadneprovskiy, N.S.Lomino, O.V.Sobol. Influence of argon on structure and properties of Ti-Si-N coatings obtained by vacuum-arc deposition in gaseous mixture nitrogen+argon // VANT, series: “Physics of radiation damage and radiation material science”, 2012.

- I.V.Vitkovskiy, A.N.Konev, S.A.Leonov, V.M.Khorochikh, V.S.Shorkin. Methodology of formation of multilayer structures of liquid metal blanket of fusion reactor. Instruments and technique of experiment, No4, 2012, p.89-93

- V.V.Vasiliev, V.E.Strelnitskiy. Method of transportation of vacuum-arc cathode plasma with filtration from micro particles and apparatus for its realization.// Patent of Ukraine of 27.02.2012, bulletin No4, 2012, C23C 14/35

- V.A.Belous, V.V.Vasiliev, S.K.Goltviyanitsa, V.S.Goltviynitsa, Yu.A.Zadnieprovskiy, B.I.Kovalenko, V.E.Strelnitskiy, G.N.Tolmacheva. Abrasive and cavitation resistance of TiN coatings alloyed by Al, Si,Y // Bulletin of engine manufacture, No1 (26), 2012, p.201-205

- A.I.Kalinichenko, S.S.Perepelkin, V.E.Strelnitsliy. Distinctions of formation of thermoelastic spikes under bombardment by heavy metals ions of low and intermediate energies. Bulletin of KNU, No991, seriesphysical, “Nuclei, particles, fields” – 2012. V. 1/53. p.29-34

- i.I.Aksenov, V.A.Belous, V.E.Strelnitskiy. Vacuum-arc surface modification and coating depositionmethods in KIPT. Ukraine (Historical review) // Society of Vacuum Coaters, 2012. Summer bulletin.

2011 year

- I.I. Aksenov, V.A. Belous, Yu.A. Zadneprovskiy, N.S. Lomino, O.V. Sobol. Features of synthesis of Ti-Si-N coatings by condensation of vacuum-arc plasma with a composite cathode // ВАНТ, Серия:Вакуум, чистые материалы, сверхпроводники, 2011, №2 (18). С. 266-273.

- V.A. Belous, V.V. Vasyliev, V.S. Goltvyanytsya, S.K. Goltvyanytsya, A.A. Luchaninov, E.N. Reshetnyak, V.E. Strel’nitskij, G.N. Tolmacheva, O. Danylina. Structure and properties of Ti–Al–Y–N coatings deposited from filtered vacuum-arc plasma // Surface & Coatings Technology 206 (2011) 1720–1726.

- D.S. Aksyonov, I.I. Aksenov, A.A. Luchaninov, E.N. Reshetnyak, V.E. Strel’nitskij. Plasma stream mixing in two-channel T-shaped magnetic filter // Вопросы Атомной Науки и Техники, Серия «Вакуум, чистые материалы, сверхпроводники» №6(76), 2011, с.116-120.

- V.A.Belous,V.M.Lunev, G.I.Nosov, G.N.Tolmacheva. Investigation of characteristics of coatings synthesized with source of gaseous plasma. Physical engineering of surface, v.9, No4, p.256-262.

- I.I.Aksenov, V.A.Belous, Yu.A. Zadneprovskiy, N.S.Lomino, O.V.Sobol. Features of synthesis of Ti-Si-N coatings by condensation of vacuum-arc plasma with a composite cathode // VANT, series: Vacuum, pure materials, superconductors, 2011, No2 (18), p.266-273.

- I.I.Aksenov, V.A.Belous, A.N.GRigoriev, I.G.Ermolenko, Yu.A.Zadneprovskiy, V.I.Kovalenko< N.S.Lomino, V.G.Marinin, O.V.Sobol, G.N.Tolmacheva. Wear resistance and heat resistance of vacuum-arc coatings on the base of TiN and TiAlN with additions of Si and Y. // VANT, Physics of radiation damage and materials science, No4, 2011, p.169-173.

- I.I.Aksenov, V.A.Belous, Yu.A.Zadneprovskiy, N.S.Lomino, O.V.Sobol. Special features of Ti-Si-N coatings obtained by deposition of vacuum-arc with a composite cathode. /Functional materials, 18 No2, 2011, p.266-273

- V.V.Vasiliyev, V.I.Kovalenko, A.A.Luchaniniv, V.G.Marinin, E.N.Reshetn`yak, V.E.Strelnitskiy, G.N.Tolmacheva. Mechanical properties and erosion resistance of vacuum-arc coatings (Ti, Al) N modified by yttrium //VANT, Series “Physics of radiation damage and radiation material science”, No4(74), 2011, p.160-164

- V.I.Gritsina, S.F.Dudnik, O.A.Opalev, E.N.Reshetnyak, V.E.Strelnitskiy. “Special; features of diamond coatings morphology with nanocrystalline structure // VANT, Series “Physics of radiation damage and radiation material science”, No4 (74), 2011, p.165-168

- D.S.Aksenov, I.I.Aksenov, A.A.Luchaninov, E.N.Reshetnyak, V.E.Strelnitskiy, G.N.Tolmacheva, S.A.Yurkov. “Physical-mechanical propertiers of TiAlN coatings deposited from mixed two-component flux of vacuum-arc plasma //VANT, series “Physics of radiation damage and radiation material scienc No4 (74), 2011.

- A.I.Kalinichenko, V.E.Strelnitskiy. Non linear acoustic response of composite to pulsed irradiation as a new channel of information about processes of failure on boundary “inclusion-matrix” // VANT, series: ”Physics of radiation damage and radiation material science”, No4(74), 2011, p.178-181

- V.E.Kutniy, A.A.Verevkin, V.I.Gritsina, S.F.Dudnik, O.A.Opalec, A.V.Ribka, V.E.Strelnitskiy, A.E.Tenishev, V.L.Uvarov, V.A.Shevchenko, I.N.Shlyakhov. Sensors of ionizing radiation on the base of CVD diamond films // Bulletin of Eastern-Ukrainian university named by V.Dal, No8 (162), 2011,p.2.2 p.128-137.

- B.P.Bereznyak, A.A.Verevkin, V.I.Gritsina, S.F.Dudnik, V.E.Kutnyi, O.A.Opalev, E.N.Reshetnyak, A.V.Ribka, V.E.Strelnitskiy. Production of self-carrying polycrystalline diamond films for detectors of ionizing radiation // VANT, series: Physics of radiation damage and radiation material science, No2(72), 2011, p.137-140.

- D.S.Aksenov, i.I.Aksenov, A.A.Luchaninov, E.N.Reshetnyak, V.E.Strelnitskiy. Plasma in two-channel T-shaped magnetic filter //VANT, series: “Vacuum, pure metals, supercinducters” No6 (76), p.116-120.