New systems for formation of plasma fluxes

With high coefficient of mass transfer of plasma forming material on article give the possibility to obtain mono and multilayer coatings with thickness to 1-2 mm.

Our equipment

Long-size cathodes:

Flat - for uniform treatment of large surfaces (the length of cathode has no principal limitations).

Chamber with planar cathode |

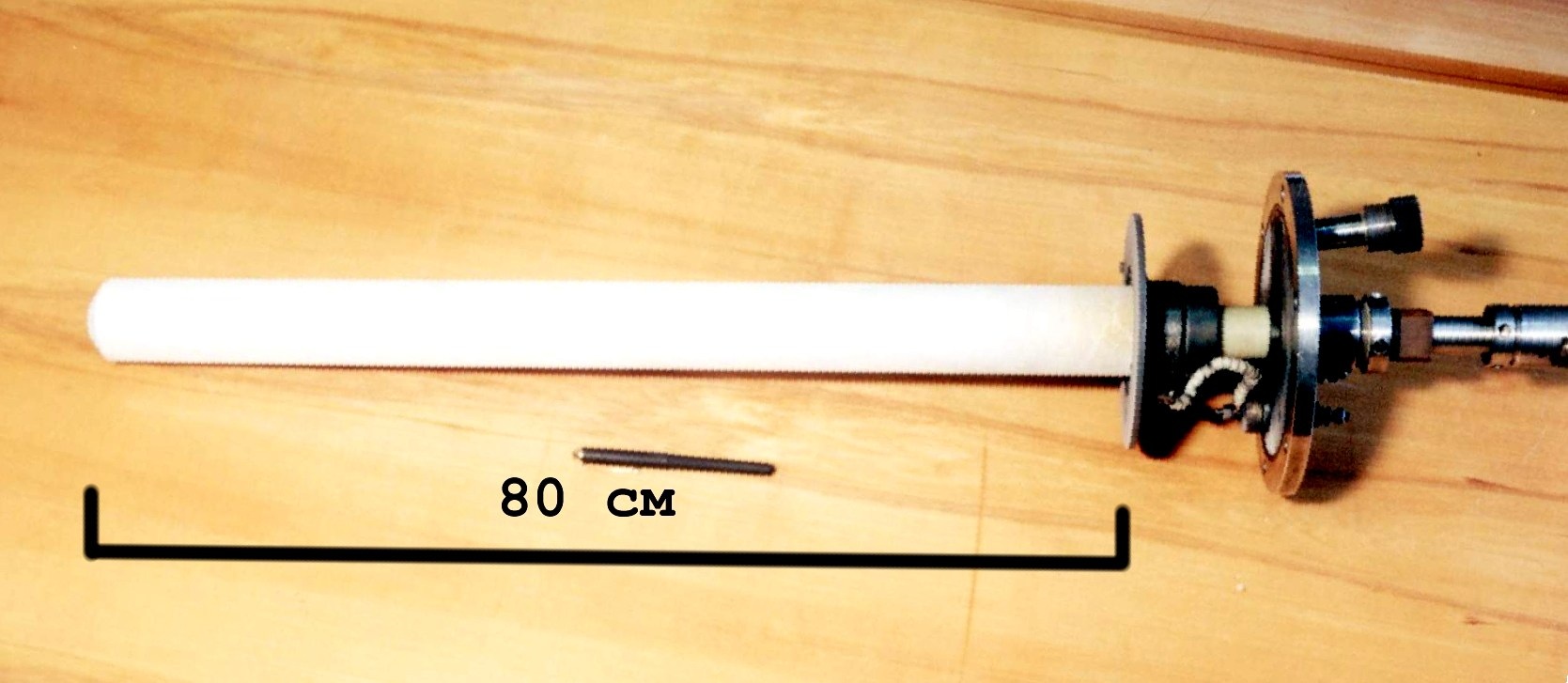

Cathode unit of long-sized evaporator with cylindrical cathode |

Complex treatment of articles

- Includes the ion nitriding in high density fluxes of plasma with the rate 10-150 mkm/hour, depth to 500 mkm and deposition of coating of necessary thickness.

- Increases the specified life of components and tools by 300-2000%.

Technology of multilayer films production

- From metallic to any compositions of metals and their compound (of the type of oxides, of nitrides, carbides) with unique properties.

- Guarantee high-efficiency increase of wear resistance and longevity of coated components.

Metallization of

Appearance and main characteristics of assembly with linear

| Diameter of cathode | 60mm |

| Current of arc: | 50-100А |

| Ion current outlet filter to: | 5А |

| Hight quality of plasma filtration | |

| Rate of coatings deposition to: | 18mkm/h |

| Effective area of coating homogeneity on diameter 180 mm(without rotation of the base) |

5%, 180mm |

High quality of filtration illustrates the image of mark on the surface of the base of monocrystalline silicon before and after coating deposition: the film reproduces well pattern of the base.

|

|

| Silicon base without coating |

the base with coating Ti with thickness 10 mkm |