Ion-plasma modifying

Ion-plasma modifying allows influence on physical-chemical properties of materials: strengthen and increase the hardness of surface, decrease the rate of creep and increase the yield strength of zirconium alloys at the expense of formation on surface of thin modified layers (to 200 nm) under influence of ion implantation (II). There are no of volume changes.

Modifying of surface in gas plasma

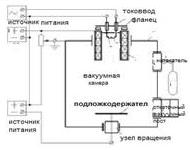

Diagram of installation with SGP

Is realized by developed in NSC KIPT of high efficiency thermal cathode source of gaseous plasma (SGP).

Parameters of SGP:

- Filament current to: 150А;

- Voltage of anode: + 70V;

- Discharge current of the source: 0.1 ... 80А;

- Vtr to: 30mkm/hour;

- Str: 0.25m2

Potential:

- Ion cleaning in inert gases

- Ion nitriding;

- Ion implantation of gaseous ions.

| Ion nitrinding (IN) | Ion implantation of gaseous ions | |

|---|---|---|

|

|

|

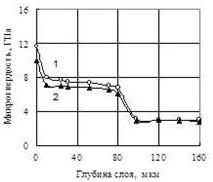

| Dependens of HV surface of die steel on the depth of nitrited layer. 1-steel 5 CrNiMo; 2- steel 5CrNiV. |

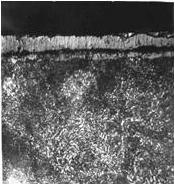

Microstructure of steel 5CrNiMo after IN during 2 hours at T = 520°C and density of nitrogen ion current 150 А /m2x400. |

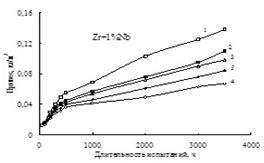

Kinetics of corrosion of specimens of ally Zr + 1% Nb after implantation of Ar+C with E=15 keV: 1 - initial speciments; 2-Di=5*1015см-2; 3-1016; 4-4*1016; 5-1017 |

Modifying of surface in metallic plasma

Independent arc discharge in metal vapors realized with electro arc evaporator of metals (EAE) is used for generation of plasma.

| Retention of corrosion of Zr alloys | Decrease of the rate of creep in Zr alloys | Influence of implantation on yield strength |

|---|---|---|

|

|

|

| APK of specimens of fuel tubes of alloy E110 in reactor water: initial(1) and after irradiation with ions of Mo+ (2,4) and Al + (3,5) at: Di=1017 ions/sm2(2,3); Di=1018ions/cm2(4,5) | Dependence of the creep rate on voltage at T = 700K of specimens of ally Zr1Nb after irradiation with Mo + 1-initial specimen; 2-after ІІ Di=1017ions/cm2; 3-Di=1018ion/cm2. |

Dependence of ultimate strength σВ(⚝) and of yield strength σ0.2( )of specimens (sections of fuel tubes), break tested on INSTRON after ion irradiation. Temperature of tests T= 350°C. |