Kinds of coatings

- Hardening

- Protecting, transparent

- Self-carrier of refractory metals

- Anticorrosive

- Thermally stable

- Antifriction

- Bactericide

- Protective – decorative

1. HARDENING

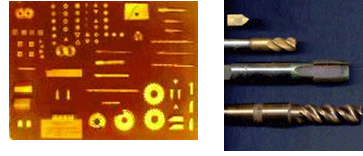

Increase service life of cutting and shape forming instrument by 300-3000% in dependence on instrument kind and treatment of material. Increase hardness of instrument up to HV 1800…8000. Are used for surface hardening of instruments:

- cuttings;

- shape forming;

- stamping;

- measuring;

- medical.

2. PROTECTING, TRANSPARENT

Protection of articles made of poly acryl from ultra-violet radiation, moisture and also mechanical, abrasive and chemical attack from contaminated atmosphere by deposition of fine (to 0,5 mkm) protecting film.

Deposition of such coatings on other materials including Si is also possible.

View of discharge into vacuum chamber on operation of Al cathode in atmosphere of N2. On the base holder-acryl specimen with size 180x180 mm.

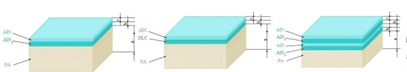

Schematic view of different multilayer combinations, used for the increase of adhesion properties: base of poly acryl-intermediate layers-upper protecting layer.

3. SELF-CARRIER OF REFRACTORY METALS

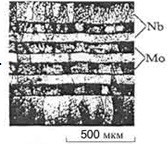

Technology of self-carrier articles production was firstly developed on the base of vacuum-arc method of deposition of thick layers of refractory metals. Models of correcting nozzles of alternating layers of molybdenum and niobium with total thickness up to 2 mm are produced.

|

|

| Details obtained on deposition of materials by layers.Thickness of the wall 1-2mm. | Photo of metallographic specimen surface. |

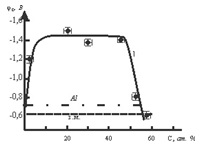

4. ANTICORROSION

|

|

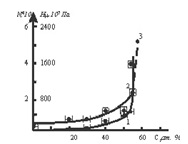

| Influence of oxygen content in coatingon value of normal electrode potential of coating (1) in solution of 0.5mmNaCl + 0.5 m; Na 2 SO 4 | Influence of oxygen content on acoustic coatingsand their microhardness (2) 3-microhardness of α-phase of Al 2 O 3 |

5. THERMALLY STABLE

|

|

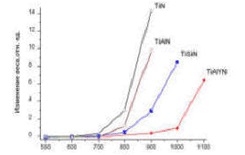

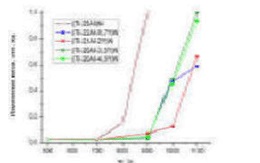

| Heat resistance of coating of different composition in atmospheric conditions | Optimization of coating composition on the base of TiAlN for increasing of their heat resistance in atmospheric conditions |

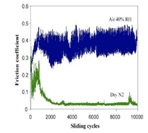

6. ANTIFRICTION

Technology is applied for production of “non wear” friction pairs, antireflection of infrared optics, in production of medicine instruments and other articles, hardening of instruments, members of video/audi equipment. Synthesis from carbon plasma. Protection of hard discs of PC and reading and recording heads.

Properties of coating:

- indifference to aggressive media;

- HV 8000…12000;

- friction coefficient 0,03

|

|

|

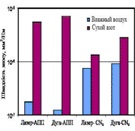

Coefficient of wear carbon coatings in pair with SiC bulb.

Comparative characteristincs of carbon films obtained by vacuum-arc and laser methods.

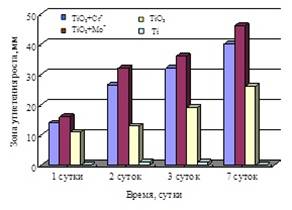

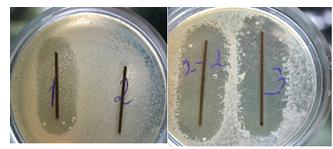

7. BACTERISIDE

Light zones – depression of the growth of E coli around implants with developed coatings.

Petri dish sowed by microorganisms St. Aureus with specimens of pure Ti coated by photocatalytic TiO2coatings (PhC).

1 – specimen with TiO2 coating;

2 – specimen of pure titanium;

2-2 – specimen with TiO2 coating irradiated with ions of Mo+;

3 – specimen with TiO2 coating irradiated with ions of Cr.

8. PROTECTIVE-DECORATIVE

These coating are of wide color scale: from gold-straw to black. They are used for coating of articles for industrial and consumer destination:

- crockery, table and kitchen accessories;

- elements of bathroom equipment;

- parts of audio/video apparatus;

- roofing metallic materials;

- tiles;

- metalware, eyeglass frames and glasses;

- mounting hardware;

- luminaires;

- furniture accessories;

- jewelry;

- watch bodies and others.