High-production methods of coatings deposition. AIS method

Purpose - spraying of nano- and microcrystalline metallic, metal-metalloid and ceramic coatings with thickness 0,001-1 mm on turbine blades, machine elements, cutting instrument, nozzles of low draft engines.

Main areas of the use - reactor materials, aviation and rocket engineering, petroleum-chemistry and petroleum processing equipment, engineering industry, medical instrument, automotive industry.

basic industrial plant AIS-3

AIS-3 with arc ionization vapor |

With HF vapor ionization |

AIS-3 - basic industrial plant Basic industrial plant AIS-3 contains electron-beam evaporator with ionizer, plasma source of ions of inert gas and electron-arc evaporator analogous to evaporator in plant of the type BULAT-6. In USSR 10 plants were produced. The chamber dimensions: diameter-1 m, height – 0,75 m.

Uniqueness and merits of installation AIS

- use of two independent sources of metallic plasma;

- presence of powerful sources of gaseous plasma;

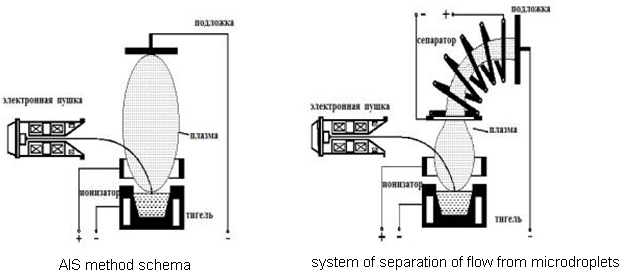

- possibility of installation of electron-beam modulus with plasma flux separation off micro drops;

- realization of high – production ecologically pure technologies.

Technical characteristics of AIS-3

| Maximal power of electric power consumption, kWt, not more | 60 |

| Supply voltage (3-phase), V | 380/220 |

| Electro-arc source of metallic plasma, pieces | 1 |

| Source of gaseous plasma, pieces | 1 |

| Electron-beam evaporator (30 kWt), pieces | 1 |

| Separator of plasma | 1 |

| System of pumping-out: ▪ electro arc pump (8000 l/s) ▪ diffusion pump (500 l/s) ▪ roughing – down pump (60 l/s) |

1 2 3 |

| Water consumption, m3/hour | 4 |

| Operating chamber, mm Diameter Height |

1000 750 |

| Useful volume of chamber, mm Diameter Height |

700 500 |

| Rate of deposition on plane on distance 0,5 mkm/hour | 70-200 |

| Acceptable load on the base spindle, kGs | 50 |

New technological processes and equipment for high-speed deposition of ion-plasma coatings by the method of atom-ion spraying (AIS)

Method of atom-ion spraying (method AIS-original author name of the method developers) is physical method of coating deposition (thick films) in vacuum by electron-beam evaporation of material, ionization of vapors of evaporated material by electron –arc dependant heavy current discharge (or HF discharge) and condensation of atom-ion flows on the base (article, piece).

Works for development and initial industrial use of the method were initiated by one of great ordering of Ministry of engineering industry of USSR (February of 1978) for anticorrosion protection of uranium materials. One of scientific collective of Kharkov institute of physics and technology (now NSC KIPT) have took part in realization of these works under the leadership of academician Zelenskiy V.F. Scientists Kartnazov G.N., Pavlov V.S., Belous V.A., Safonov V.I., Sleptzov S.N., Rastorguev V.P. and others were the participants of these works.

The method had combined the merits of electron-arc and ion-plasma methods of coating deposition – high capacity (rates of coatings deposition reaches ~0,1-1mkm/s) and degree of vapor streams ionization (10…70%).

Systems of complete cleaning of plasma from microdrops and neutral particles with high index of plasma passage trough the separator (to 50%).Sputtered materials may be metals and their compounds as oxides and carbides and others.

Coatings as compounds may also be formed under only the metal sputtering if deposition is carried out in atmosphere of one of active gas or in the mixture of gases (similar to possibilities of other ion-plasma methods).

Method of ionization by arc discharge conditions the unique charge and low initial energy of ions (5-7 eV) which guarantees the formation of practically mono energetic flux of electrically accelerated ions. This allowed to perform the mathematical modeling of processes of deposition of multi components coatings, develop the physical model of ion compacting of building up condensates, develop the physical base of formation of some technological processes.

Theses investigations have contributed to formation of one of new branch of solid state physics – of ion metallurgy. New materials with unique properties were formed by proposed method, also on the base of developed metastable diagrams of systems metal-metalloids. These diagrams are characterized by the presence of metastable compounds, of supersaturated solid solutions with limited solubility exceeding the equilibrium values in 103-104 times, of structures of amorphous and nanocrystalline kind at condensation temperatures up to 900 K and others.

Atom-ion sputtering allows to obtain in short period of time (few hours) thick ion-plasma coatings (1-2 mm) and self-carrier massive articles (by the method of layers building up on the base) with specific properties. The value of technological effect in such coatings frequently attains 10-fold increase of service parameters of usual materials.

Developments are defended by patents of USSR, including patent of USSR C 23 C 14.00.Ways of coating deposition in vacuum/ Belous V.A., Kartmazov G.N., Safonov V.I. and others. Discovery. Inventions. 1986 N40. Author certificate is transformed into patent of Ukraine N 47545. 15.07.2002. Bulletin N.7.

Our possibilities:

Technological, researching.

Possible areas of industrial (practical) use:

- evaporation of ceramics, pure metals and alloys;

- reduction of wear -out surfaces;

- production of thin-walled self-carrier articles;

- substitution of electroplating processes;

- dimension of coated article (cylinder) – diameter 350 mm, length – to 600 mm, max tare of deposition 0,1-1mm/hour.

Collaboration

- joint development of new technologies and its subsequent realization;

- organization of joint enterprises for development and production of new models of facilities AIS;

- conclusion of agreements for development of technological processes for deposition of protecting coatings on articles of complicated geometry (blades, details of machines, cutting instruments, assemblies of presses and other).