High-production methods of coatings deposition Thermal-diffusion method

In our departmment are developed technologies and equipment for deposition of multi purpose protecting coatings, especially, of anti corrosion and erosion-proof coatings on the base of silicides, borides, carbides, nitrides and oxides of different metals and also of combined protecting films. Coatings may be deposited on articles made of refractory metals and alloys, graphite and carbon-carbon composition materials, alloyed and non-alloyed steels, pig iron and refractory alloys.

Development engineers: professor Zmiy V.I. and senior scientist Ruden`kiy S.G.

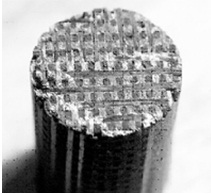

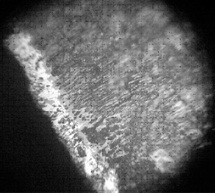

Photomicrography of specimen UUKM

original |

with coating |

Equipment

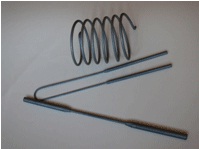

Laboratory and test-industrial equipment is used which allows deposit coatings on articles dimensions of which are inscribed into cylinder Ф=300 mm and h=400 mm. Treatment is carried out in vacuum under pressure 10-4…10-5mm and temperature 1000…1700°C.

Facility of activated diffusion saturation in vacuum for production of multi purposes complex coatings:

- of high-temperature refractory on carbon and metallic structural materials;

- of wear-resistant and anti- corrosion on steels;

- of strengthening and hard on cutting instrument, drills, bearings and others.

Used researching equipment:

- X-ray diffraction analysis – diffractometer DRON-3,0;

- Metallographic equipment – metal microscope MMR-4, MMO-1600 with hardware;

- Ultrasonic powder distributing device UZDI-2;

- Spectral analysis – spectrograph SP-30, MFS-8, spectroprojector DSP-1, microdensitometer MF-2;

- Determination of porosity by the method of hydrostatic weighing;

- Preparation of specimens for investigation by chemical method.

Activated diffusion saturation in vacuum

This method differs from well-known diffusion methods by introduction in vacuum operation zone of measured quantity of activators (on the base of metals halogenides of metals) and/or liquid-phase media which guarantees to the method the following advantages:

- possibility to obtain pure surfaces;

- high rate of coatings deposition – 10…100 mkm/hour

- temperature of saturation may be decreased by 300°C in comparison with non-activated saturation (temperatures 800-1300°C);

- possibility to obtain coatings with thickness to 1000 mkm;

- high uniformity of coating thickness on articles of complicated configuration, including articles with thread or invisible cavities;

- high diffusion strength of coating adhesion with base (on the level of strength of basic metal);

- recycled waste and ecological purity of production.

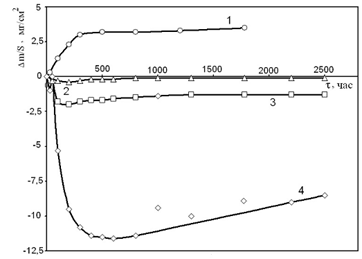

Corrosion resistance of steel 20 with protecting coating at temperature 280°C and pressure 63 atm:

1-boron-chromed steel;;

2-chromium-plate steel;

3-basic steel;

4-boron steel.

Hight-temperature |

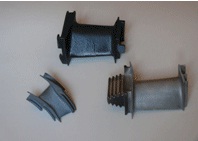

Microchamber and gas -distributor for |

|

Turbine blades of |

Graphite crucibles |

Real use of the method of multi purpose protecting coatings on structural materials used in different field of science and technique will increase serviceability of machines and mechanisms which will operate in conditions of high temperatures, corrosion active madia, erosion wear, active melt etc.

| Graphite brand | Composition of protecting coating | Heat resistance | |

|---|---|---|---|

| Temperature of tests, °С | Time to failure | ||

| АРВ | SiC+(W,Co)Si2 | 1500 | 15,0 |

| MPG | SiC+(W,Co)Si2 | 1500 | 21,0 |

| UUMK | SiC+HfB2+MoSi2 | 1500 | 32,0 |

| MPG | SiC+HfB2+MoSi2 | 1700 | 20,5 |

| АРВ | SiC+HfB2+MoSi2 | 1800 | 8,0 |

| АРВ | SiC+HfC+MoSi2+(ZrO2+SiO2) | 1800 | 6,0 |

| UUKM | SiC+TiC+ HfB2+WSi2 | 1800 | 7,0 |

| UUKM | SiC+TiC+ HfB2+WSi2 | 1950 | 1,0 |